Fasteners and Machining: Customized Solutions for every single Production Need

Fasteners and Machining: Customized Solutions for every single Production Need

Blog Article

Browsing the World of Fasteners and Machining: Approaches for Precision and Rate

In the elaborate realm of bolts and machining, the mission for accuracy and rate is a perpetual difficulty that requires precise attention to detail and calculated planning. From understanding the diverse selection of fastener kinds to picking ideal products that can withstand extensive needs, each action in the process plays an essential duty in attaining the desired result. Accuracy machining strategies even more raise the intricacy of this craft, calling for a fragile balance in between technical knowledge and ingenious strategies. As we look into the techniques that can boost both speed and effectiveness in this domain name, the interaction in between top quality control measures and operational excellence becomes a critical focal factor.

Understanding Fastener Types

When selecting fasteners for a project, comprehending the various types readily available is crucial for ensuring optimal efficiency and dependability. Screws are used with nuts to hold products with each other, while screws are versatile fasteners that can be made use of with or without a nut, depending on the application. Washers are vital for dispersing the load of the fastener and preventing damage to the product being attached.

Selecting the Right Materials

Comprehending the value of selecting the best products is paramount in guaranteeing the ideal efficiency and integrity of the chosen fastener types went over formerly. When it pertains to bolts and machining applications, the product selection plays a vital duty in determining the overall stamina, durability, corrosion resistance, and compatibility with the desired environment. Different materials provide varying homes that can dramatically influence the efficiency of the bolts.

Usual products made use of for bolts consist of steel, stainless-steel, brass, light weight aluminum, and titanium, each having its unique toughness and weak points. Steel is renowned for its high toughness and durability, making it suitable for a variety of applications. Stainless-steel offers exceptional rust resistance, ideal for settings vulnerable to moisture and chemicals. Light weight aluminum is lightweight and corrosion-resistant, making it ideal for applications where weight decrease is crucial. Brass is commonly selected for its aesthetic allure and exceptional conductivity. Titanium is understood for its outstanding strength-to-weight ratio, making it ideal for high-performance applications. Picking the ideal material entails thinking about elements such as toughness demands, environmental problems, and spending plan restrictions to ensure the wanted performance and long life of the bolts.

Precision Machining Techniques

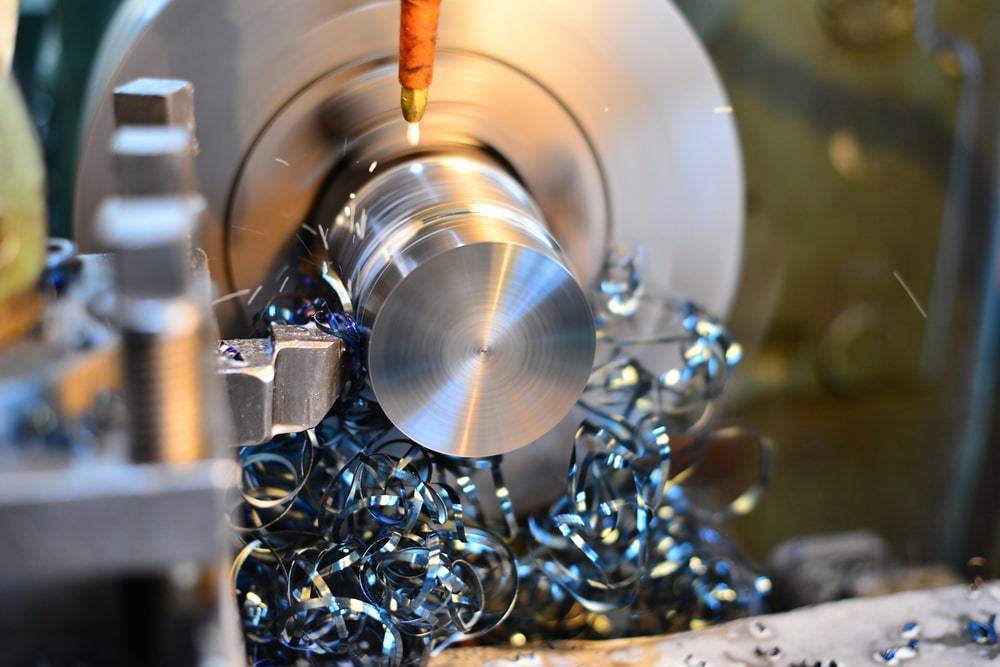

Along with CNC machining, other accuracy methods like grinding, transforming, milling, and drilling play essential roles in fastener manufacturing. Grinding helps attain great surface finishes and limited dimensional tolerances, while turning is often utilized to create round components with precise diameters. Milling and drilling operations are crucial for forming and developing openings in bolts, guaranteeing they fulfill exact specifications and feature appropriately.

Enhancing Rate and Performance

To enhance bolt production procedures, it is vital to simplify procedures and carry out efficient strategies that match precision machining strategies. One crucial strategy for improving speed and effectiveness is the implementation of lean manufacturing principles. By lowering waste and concentrating on continuous improvement, lean techniques aid optimize and eliminate traffic jams process. Furthermore, buying automation modern technologies can substantially boost manufacturing speed. Automated systems can manage recurring tasks with accuracy and speed, allowing workers to concentrate on more complicated and value-added activities. Taking On Just-In-Time (JIT) supply monitoring can also improve efficiency by making certain that the right materials are available at the right time, lessening excess supply and minimizing preparations. Promoting a society of collaboration and interaction amongst team participants can boost general efficiency by advertising transparency, problem-solving, and technology. By combining these methods, manufacturers can achieve a balance between rate and precision, inevitably improving their competitive edge in the fastener market.

Top Quality Control Steps

Executing extensive quality assurance steps is essential in making certain the dependability and uniformity of bolt products in the production procedure. Quality i loved this control steps incorporate numerous stages, beginning with the choice of raw products to the last evaluation of the completed fasteners. One basic facet of quality assurance is carrying out comprehensive product assessments to validate conformity with specifications. This entails evaluating aspects such as product toughness, make-up, and toughness to assure that the bolts satisfy market requirements. Furthermore, checking the machining refines is essential to promote dimensional precision and surface finish top quality. Using sophisticated innovation, such as automated examination systems and accuracy measuring tools, can improve the precision and performance of high quality control procedures.

Regular calibration of equipment and equipment is imperative to keep uniformity in manufacturing and make sure that fasteners satisfy the required resistances. Implementing rigorous protocols for determining and addressing flaws or non-conformities is important in stopping substandard items from entering the market. By establishing a comprehensive quality assurance structure, manufacturers can support the track record of their brand name and supply fasteners that meet the highest requirements of efficiency and toughness.

Final Thought

In the detailed world of bolts and machining, the pursuit for accuracy and rate is Discover More Here a continuous difficulty that demands careful interest to detail and calculated planning. When it comes to fasteners and machining applications, the material selection plays a vital role in identifying the general stamina, sturdiness, rust resistance, and compatibility with the intended atmosphere. Precision machining entails numerous sophisticated techniques that guarantee the tight tolerances and requirements needed for fasteners.In addition to CNC machining, various other accuracy methods like grinding, turning, milling, and exploration play crucial functions in fastener manufacturing.To maximize fastener production procedures, it is vital to improve operations and apply effective strategies that enhance accuracy machining methods.

Report this page